News

What Makes the Predeus Si DRIE System the Leading Choice for Advanced Etching Processes

At SPP Technologies, we proudly present the Si DRIE system “Predeus“, equipped with our proprietary plasma source, showcasing its outstanding processing capabilities. This article highlights several key performance examples of the Predeus system, demonstrating its advanced etching performance and precision.

What is Si DRIE?

Si DRIE stands for Silicon Deep Reactive Ion Etching. It is an advanced etching technique used to create deep, high-precision features in silicon wafers, commonly used in MEMS (Micro-Electro-Mechanical Systems), semiconductor devices, and other microelectronics applications. Si DRIE is commonly associated with the Bosch process, a popular etching method that alternates between plasma etching and passivation steps to achieve high etching rates and precise control over feature dimensions.

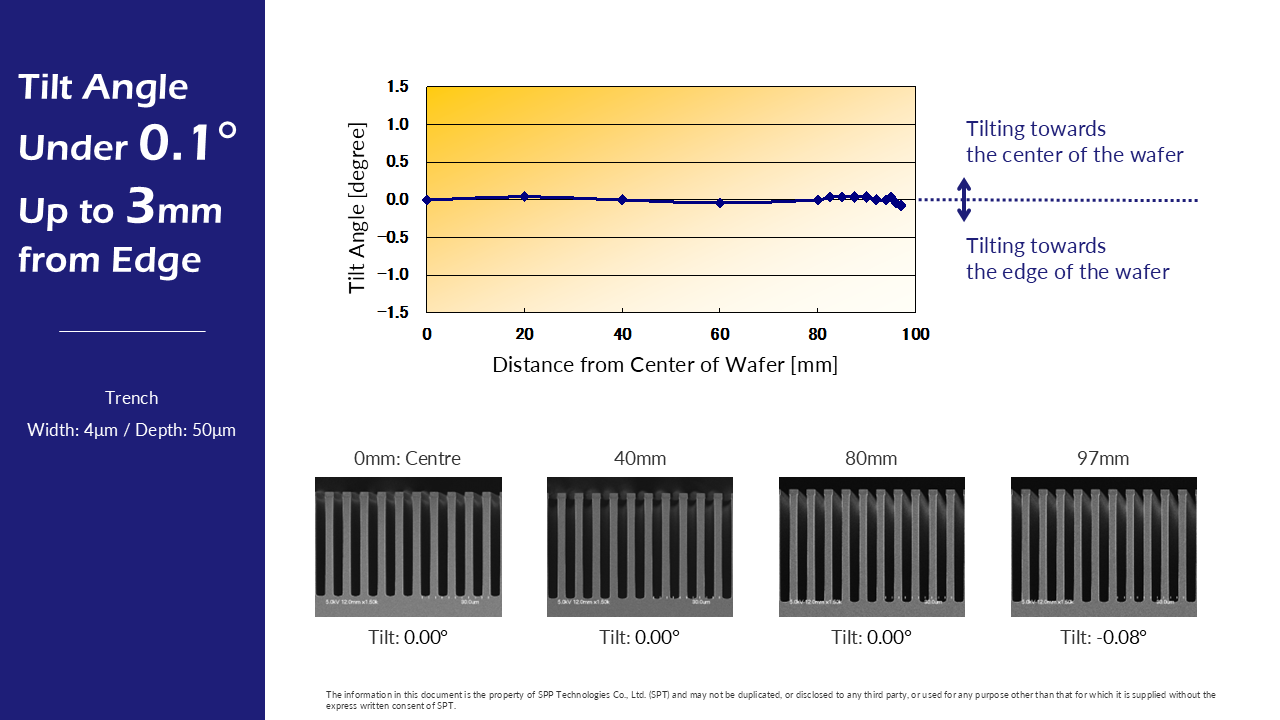

Tilt Variation Control

The Predeus system offers exceptional stability in tiltting control, reducing variations to below 0.1° up to the 3mm edge of a 200mm wafer. This precision ensures consistent results, even in delicate etching processes.

Performance Highlights:

– Stable tilt angle below 0.1° at the edge (3mm) of a 200mm wafer.

– Trench Width: 4µm

– Etching Depth: 50µm

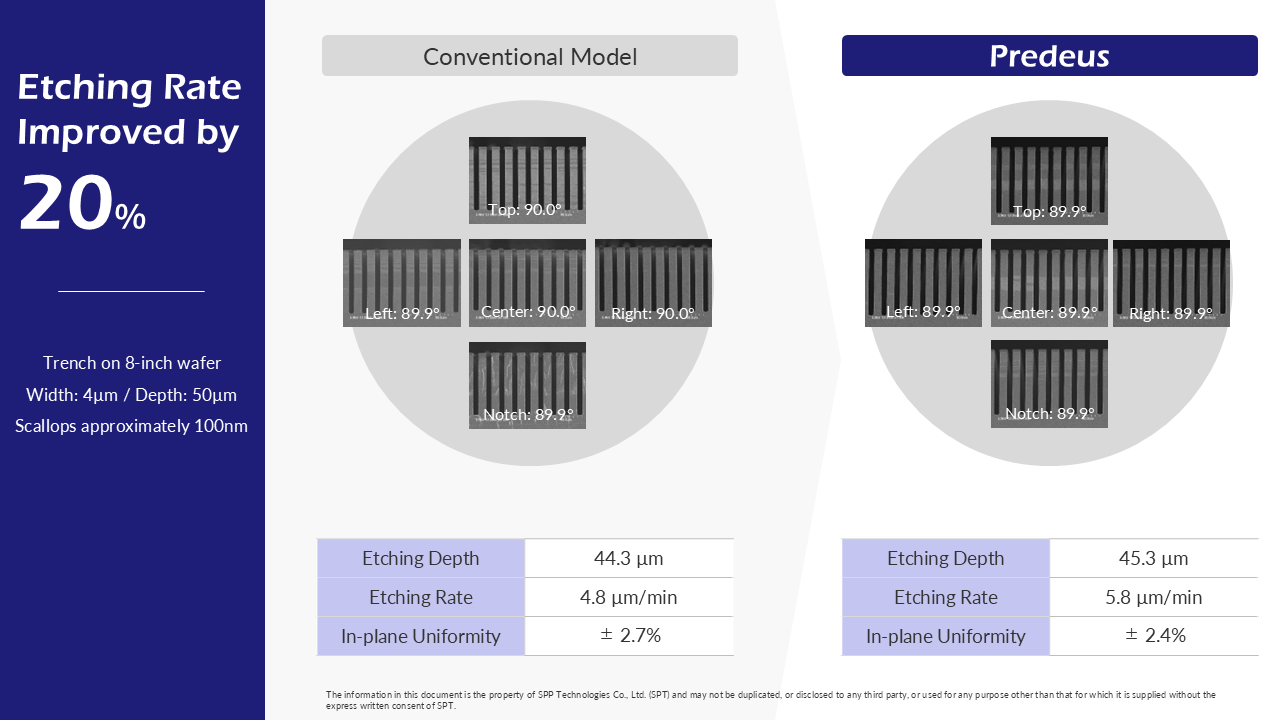

Etching Rate Comparison: Conventional Model vs. Predeus

One of the key advantages of the Predeus system is its improved etching rate. Compared to our previous model, the Predeus system delivers a 20% increase in etching rate, from 4.8µm/min to 5.8µm/min.

Performance Highlights:

– Etching Rate: 5.8µm/min (Predeus) vs. 4.8µm/min (Conventional Model).

– Sidewall Angle: Maintains excellent results, with sidewall angles comparable to the conventional model.

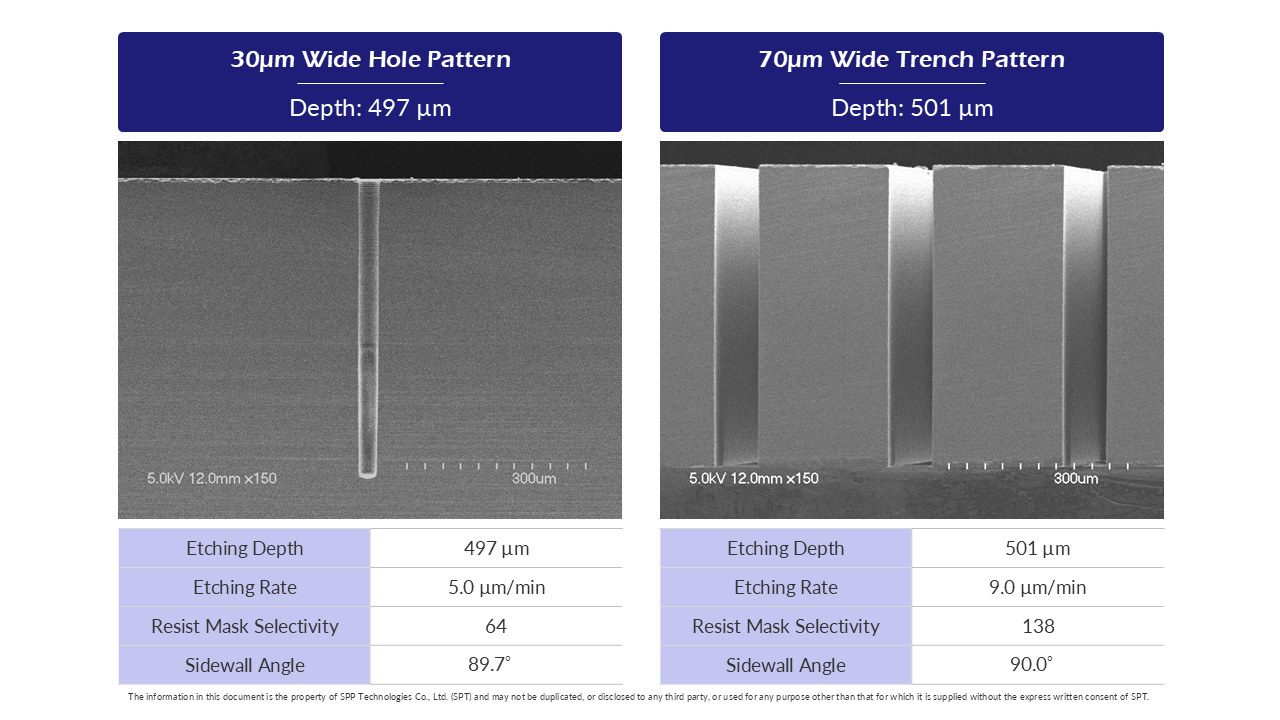

Silicon Deep Etching Example

The Predeus system excels in silicon deep etching, providing precise control and excellent performance.

30µm Wide Hole Pattern

– Etching Depth: 497µm

70µm Wide Trench Pattern

– Etching Depth: 501µm

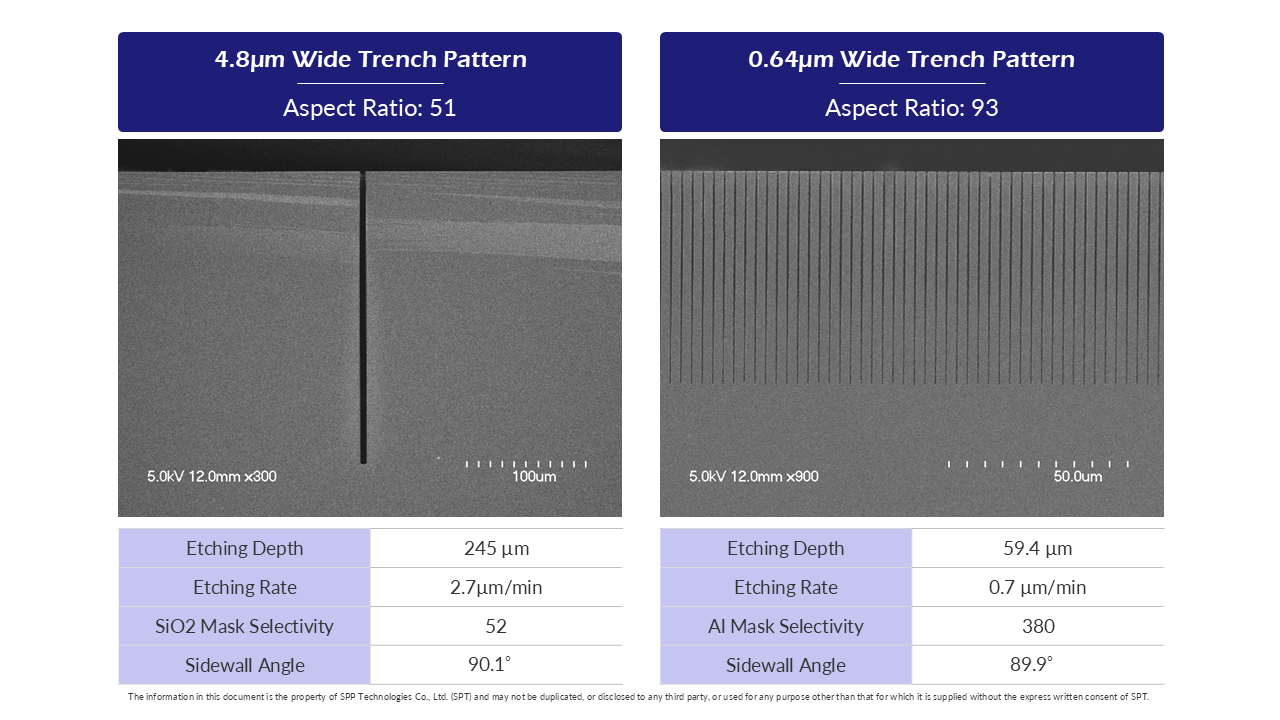

High Aspect Ratio Silicon Etching

Predeus also delivers impressive results in high aspect ratio silicon etching, achieving excellent etching precision even at narrow widths.

4.8µm Wide Trench Pattern

– Aspect Ratio: 51

– Etching Depth: 245µm

0.64µm Wide Trench Pattern

– Aspect Ratio: 93

– Etching Depth: 59.4µm

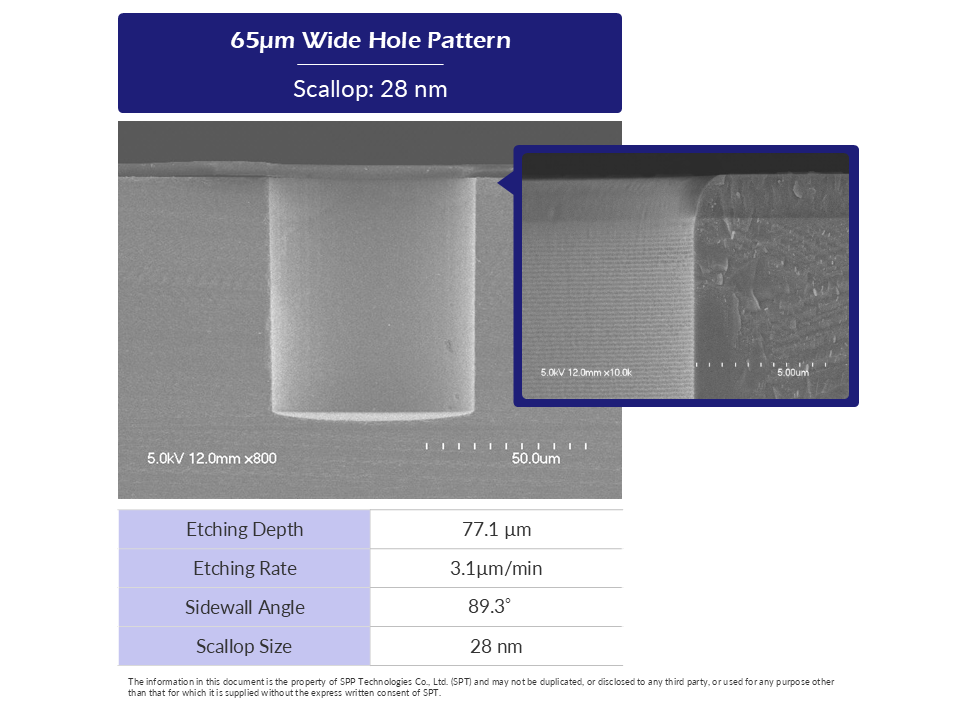

Low Scallop Silicon Etching

For processes requiring minimal scalloping, such as MEMS and microelectronics, Predeus achieves extremely low scallop formation, ensuring high-quality results.

65µm Wide Hole Pattern

– Scallop Size: 28 nm

– Etching Depth: 77.1µm

– Etching Rate: 3.1µm/min

Bosch Process and Si DRIE Technology

The Bosch process, used in Si DRIE, is a critical technology in the fabrication of MEMS. By alternating between plasma etching and passivation steps, the Bosch process enables high etching precision with high aspect ratios and deep etching depths. Predeus is designed to perform exceptionally well with this advanced process, providing superior etching rate, sidewall quality, and uniformity.

Conclusion

SPP Technologies’ Predeus Si DRIE system sets a new standard in precision etching for MEMS, semiconductors, and advanced microelectronics. With its ability to achieve superior tilting control, faster etching rates, and exceptional etching quality for both deep and high aspect ratio processes, the Predeus system is the ideal choice for advanced manufacturing applications.

Explore the full potential of Predeus, Si DRIE system—get in touch with our team to discuss your specific needs.

Contact About Equipment

+81 6-6489-5997

Get Product Support

+81 6-6489-5848

Have questions or need assistance?

Get in touch via email.